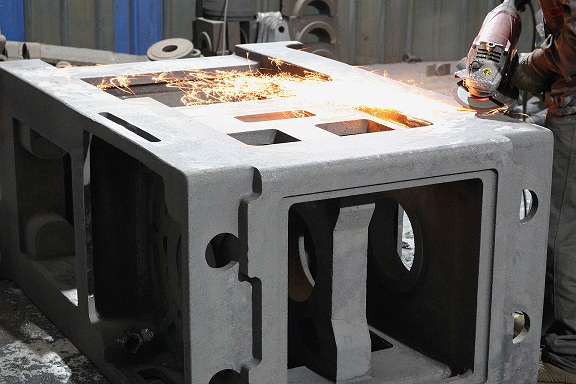

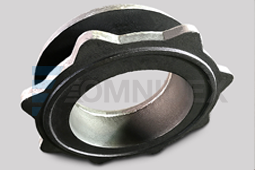

Sand Casting can be used to make a diverse range of products, including very large casting pieces. Materials are relatively inexpensive and can resist deformation in tough conditions.

Just like any other processes, Sand Casting does have its limitations (such as a higher level of waste), but in the hands of experts and specialists, it is by far the best process to use when producing large, complex components with extremely close tolerances.

If you are looking for a Sand Casting specialist to help you with your next project, don’t hesitate to contact us. You can also learn more about other casting processes on this website.