Assembly

Our assembly line is composed of experienced workers, supervised by our in-house engineers. We are proud of our craftsmanship in the manufacturing of mining equipment. We operate a versatile and cost-effective assembly line capable of handling a wide range of mining equipment.

Assemble operation

Assemble operation

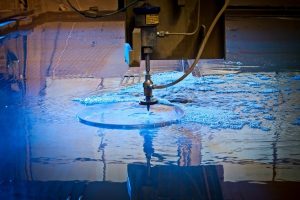

Material cutting technique

Our facilities offer laser, water jet and plasma cutting, each suited for different purposes.

Laser cutting

Water jet cutting

Welding

All welding processes are carried out by our dedicated team of skilled welders to ensure quality and reliability.

Aluminum welding

ARC welding

Surface finishing

We are also specialized in metal surface finishing. For example, our standard procedure for steel parts involve treating with zinc phosphate before powder coating or spray painting.

Powder coating

Wet painting

Our extensive experience in the manufacturing industry enable us to tackle every challenge posed by the mining industry. With over 18 years of experience in the industry, we are well-aware of the harsh conditions these mining equipment faces every day.

We treat every order with a meticulous mind and engineer our products to the highest standards. We are confident that every piece of equipment we make can withstand the elements and perform to your satisfaction.

We are eager to utilize our expertise to help you advance in the mining industry. Contact us to learn more on our assembly line.

Navigation

Contact us

Phone no.:

Asia Pacific, South America, Africa and the rest of the world: +86 20 8388 7080

UK: +44 (0) 7769 633868

Omnidex Mining Brochure

If you are looking for Industrial Mining Equipment & Machinery services, our brochure is a great way to discover what Omnidex has to offer. You can download HERE to learn more.

Copyright © 2023 Omnidex Mining. All rights reserved.

Privacy Overview

Thank you So Much !!

Thank you for contacting us! We have received your enquiry and will get back to you within 24 hours. Until then, you can give us a call at +86 20 8388 7080 anytime or email mining@omnidexgroup.com or check out our Mining Brochure for more details