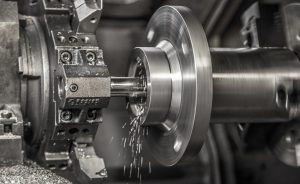

Precision Machining

Many modern industrial equipment requires high-precision parts that are difficult to make with traditional manufacturing processes. The solution to this problem is CNC machining.

CNC stands for ‘computer numerical control’. The technology employs computer-controlled mills or lathes to make the desire part out of a block of material. This process is fully automated with extremely high precision and accuracy. It is also suitable for a wide range of metals and alloys.

As an expert in mining equipment, we are well-aware of the need for large CNC machining in the mining industry. Omnidex Mining specializes in the manufacturing of super-size parts, and our precision machining capabilities includes extra-large bed size machines capable of machining these incredibly large parts.

CNC Milling

A CNC milling machine uses a rotating multi-point cutting tools to progressively remove material from the workpiece to produce a part or product.

We possess a range of three, four or five axis industrial grade CNC milling machines, built by reputable manufacturers from USA, Germany, Japan, Taiwan and China. 3 axis machines are used for simple work, while 4 axis and 5 axis machines can handle more complicated shapes.

• Maximum part size: 20 m x 4 m x 3 ms

• Maximum machining area: 12 m x 3.5 m x 2.5 m

CNC Lathe (Turning)

A CNC lathe machine rotates the workpiece in a spindle while a fixed cutting tool slices chips off of it. This process is ideal for cylindrical parts that have symmetry around the same axis.

• Maximum part diameter: 2.5 m

Navigation

Contact us

Phone no.:

Asia Pacific, South America, Africa and the rest of the world: +86 20 8388 7080

UK: +44 (0) 7769 633868

Omnidex Mining Brochure

If you are looking for Industrial Mining Equipment & Machinery services, our brochure is a great way to discover what Omnidex has to offer. You can download HERE to learn more.

Copyright © 2023 Omnidex Mining. All rights reserved.

Privacy Overview

Thank you So Much !!

Thank you for contacting us! We have received your enquiry and will get back to you within 24 hours. Until then, you can give us a call at +86 20 8388 7080 anytime or email mining@omnidexgroup.com or check out our Mining Brochure for more details