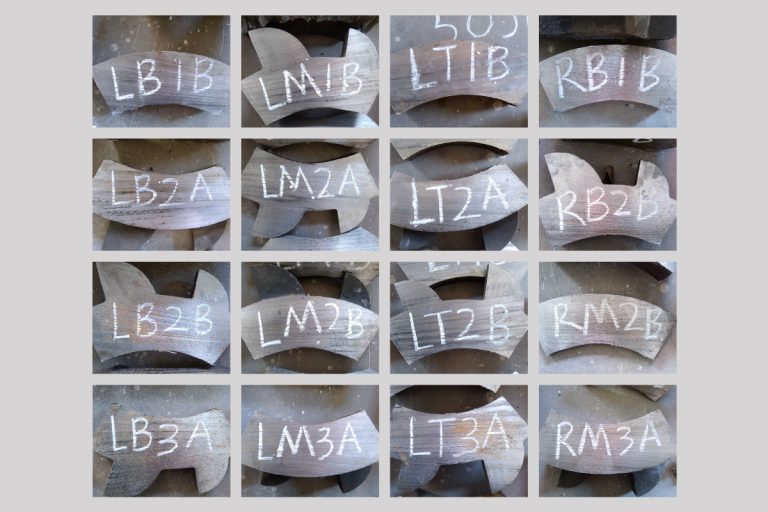

Visual Inspection

Visual inspection is required to ensure genuine quality from start to finish. In terms of casting quality control, every part is meticulously inspected by our QC experts, making sure they are fully filled (no cracking, tearing, holes, non-fill, etc.) with no distortions, bends or finishing defects. Products are also cross-checked against the quality control plan and written process instructions before moving forward to other processes.

Previous

Next